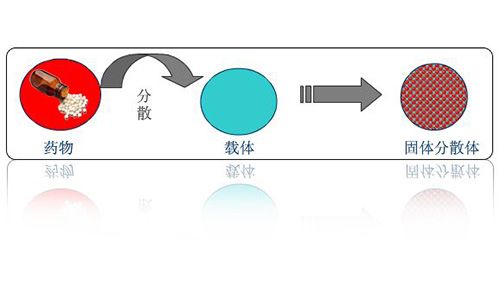

Solubilization technology

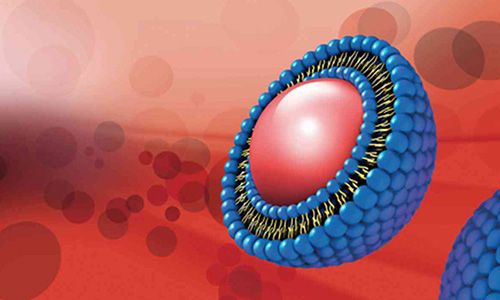

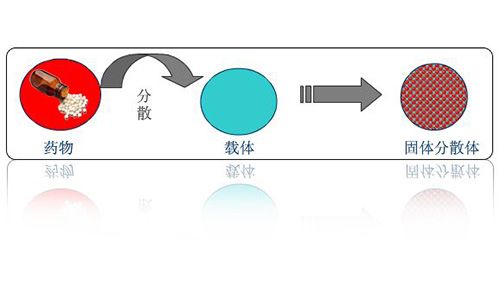

- Solid dispersion, lipid formulation

- Improve the bioavailability of poorly soluble drugs

Oral rapid release

- Oral soluble film, orally disintegrating tablet

- Extremely rapid release into the bloodstream for fast onset of action

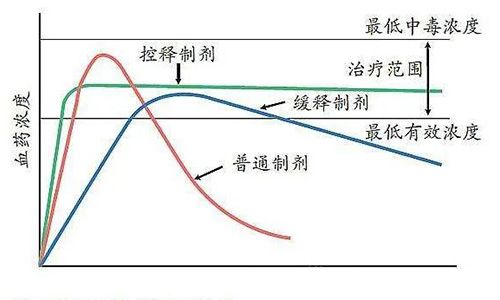

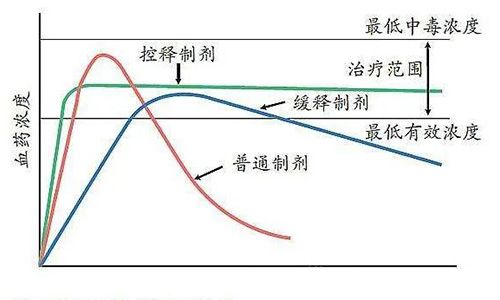

Oral sustained-release and controlled-release

- Hydrophilic gel, matrix and film

- Lower blood peak concentration and trough concentration, minimize side effects and improve patient compliance

Gastric retention technology

- Floating, interception, sinking

- Improve patient compliance, enhance BA (absorption in the upper gastrointestinal tract) and long-acting

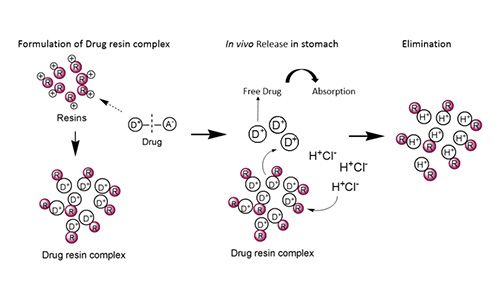

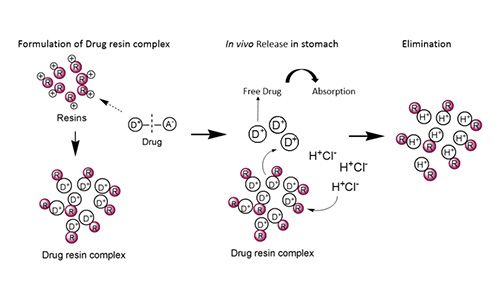

Taste-masking technology

- Primarily based on isolation and adsorption, supplemented by dilution

- Improve patient compliance